Aluminum alloy high-pressure die casting refers to a method in which liquid aluminum alloy flows from the pressure chamber into the casting cavity at an extremely fast speed under high temperature and high pressure, and forms a casting after cooling.

Aluminum parts are formed under high temperature and high pressure. The molten metal is filled into the mold at high pressure and high speed, and then crystallizes and solidifies under high pressure to form the casting. Aluminum parts are prone to defects. How to solve these defects?

- Cold shut-off problem:Properly increase the pouring temperature and control it at 640°-680°C (can be adjusted according to the product and aluminum material). Properly increase the mold temperature to increase the injection pressure and shorten the filling time. During the debugging process of the die-casting machine, the speed of the punch should be appropriately increased, and the cross-sectional area of the inner gate should increase at the same time. Improve exhaust filling conditions. Choose appropriate alloys to improve the fluidity of molten metal.

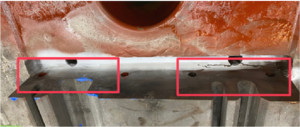

- Crack problem: Correctly control alloy composition. Change the structure of the casting, increase the rounded corners, increase the draft angle, reduce the wall thickness difference, change or increase the ejector pin, and make the ejection force uniform. Check whether the mold is dislocated or deformed, and shorten the mold opening or core pulling time.

- Stomatal problem: Check whether the oxygen pore release agent is sprayed too much, and whether the concentration of the release agent is within the appropriate range. During the debugging process of the die-casting machine, select an appropriate slow speed, check whether the exhaust area is large enough, whether it is blocked, and whether the position is located at the last filling place to improve exhaust. Is the mold temperature too low?

- The problem of shrinkage cavities: reduce material in thicker parts of the product. Increase local cooling, spray release agent, and lower mold temperature. If the shrinkage cavity is located in the direction of the sprue, a new sprue can be added for direct feeding. Using the extrusion process, a new extrusion pin is added to force the shrinkage to squeeze, when the shrinkage hole is in a semi-solid state.

- Deformation problem:Improve casting layout. Adjust the mold opening time. Reasonably set the position and number of ejector pins. Choose a reasonable method to remove the gate. Increase the draft angle to eliminate strained locations. Check whether the surface is deformed due to shot blasting, sandblasting, or accidental dropping or knocking.

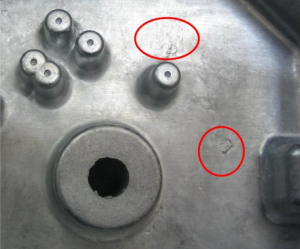

- Burr problem:Check the clamping force of the machine. Check the mold closing condition and whether the mold is dented. Check whether the mold material meets the requirements. Check whether the casting pressure is too high during the debugging process of the die-casting machine. The melting temperature needs to be controlled at 740°C-780°C.

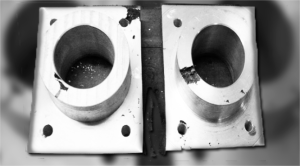

- Mold erosion and cracking problems:Check the injection ratio. The cross-sectional area of the punch, the cross-sectional area of the inner gate are generally controlled at 13-16 times. If it is too high, the width and thickness of the inner gate must be increased. Check whether the mold material complies with regulations. Check whether the mold has reached the design life, if so, the mold will be damaged. In addition, the coating process can also be used to perform special exterior treatment on the severely eroded parts of the mold. During the debugging process of the die-casting machine, appropriately reduce the high speed of the punch.

- Ripple problem:Improve filling mode and shorten filling time.

- Mold sticking problem:Increase the draft angle of the product. The mold is newly added with cooling, and spraying water is added locally during the die-casting process to reduce the mold temperature. Add ejector pin to the mold. If the fixed mold is stuck, you can consider adding a fixed mold ejector mechanism, and you can also add an undercut to the movable mold.

- Carbon deposition problem: Reduce the amount of release agent sprayed, increase the mold temperature, select a suitable release agent, and use soft water to dilute the release agent. Shorten the filling time, change the filling mode, gate position and gate speed. Check the mold strength peeling problem: Is it enough to switch to high speed early?

- Under-casting problem:improve the quality of molten metal. Increase pouring temperature or mold temperature. Improve die-casting injection pressure and filling speed. Improve the diversion method of molten metal in the gating system, and add overflow grooves and exhaust grooves in under-cast parts.