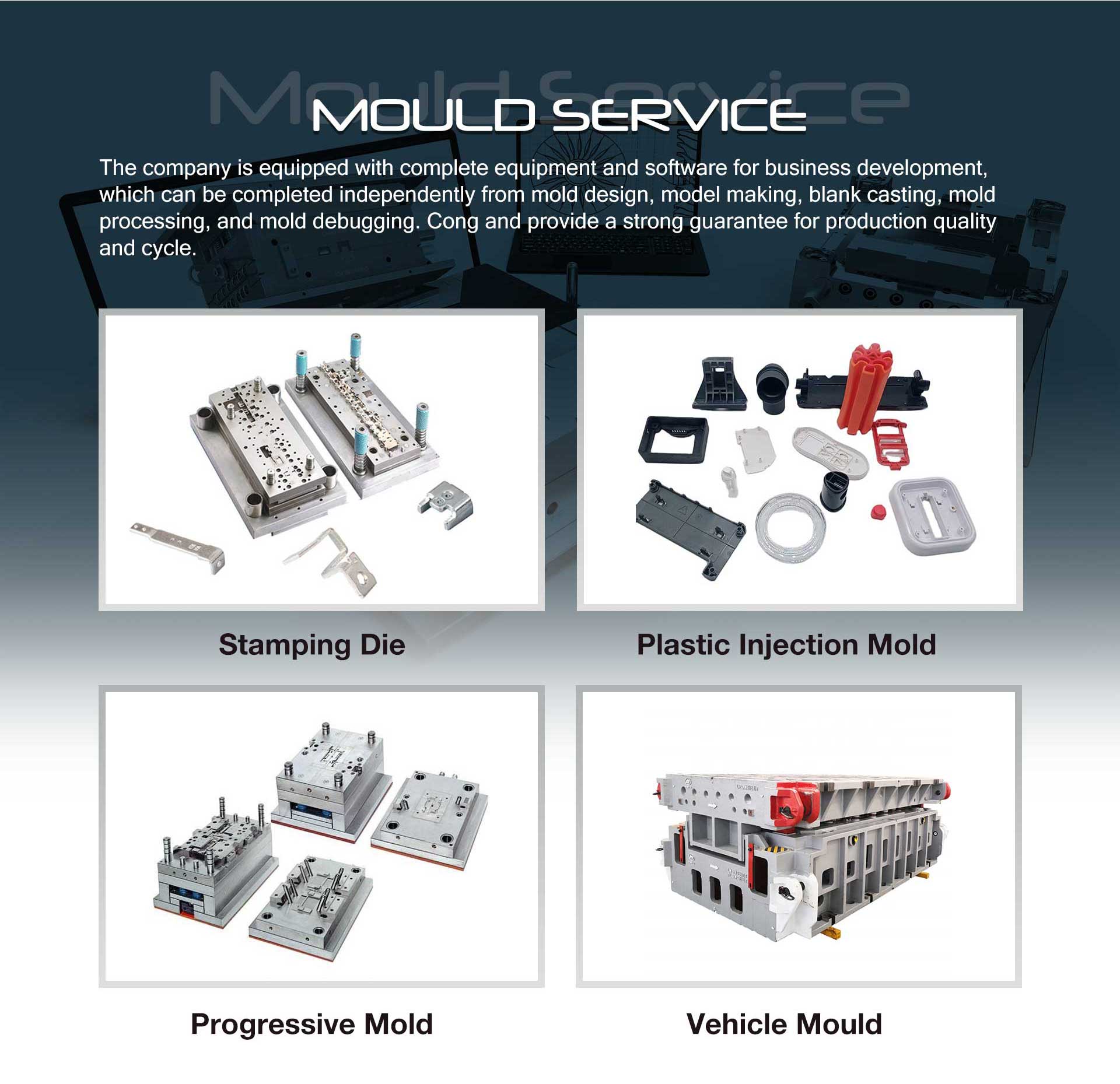

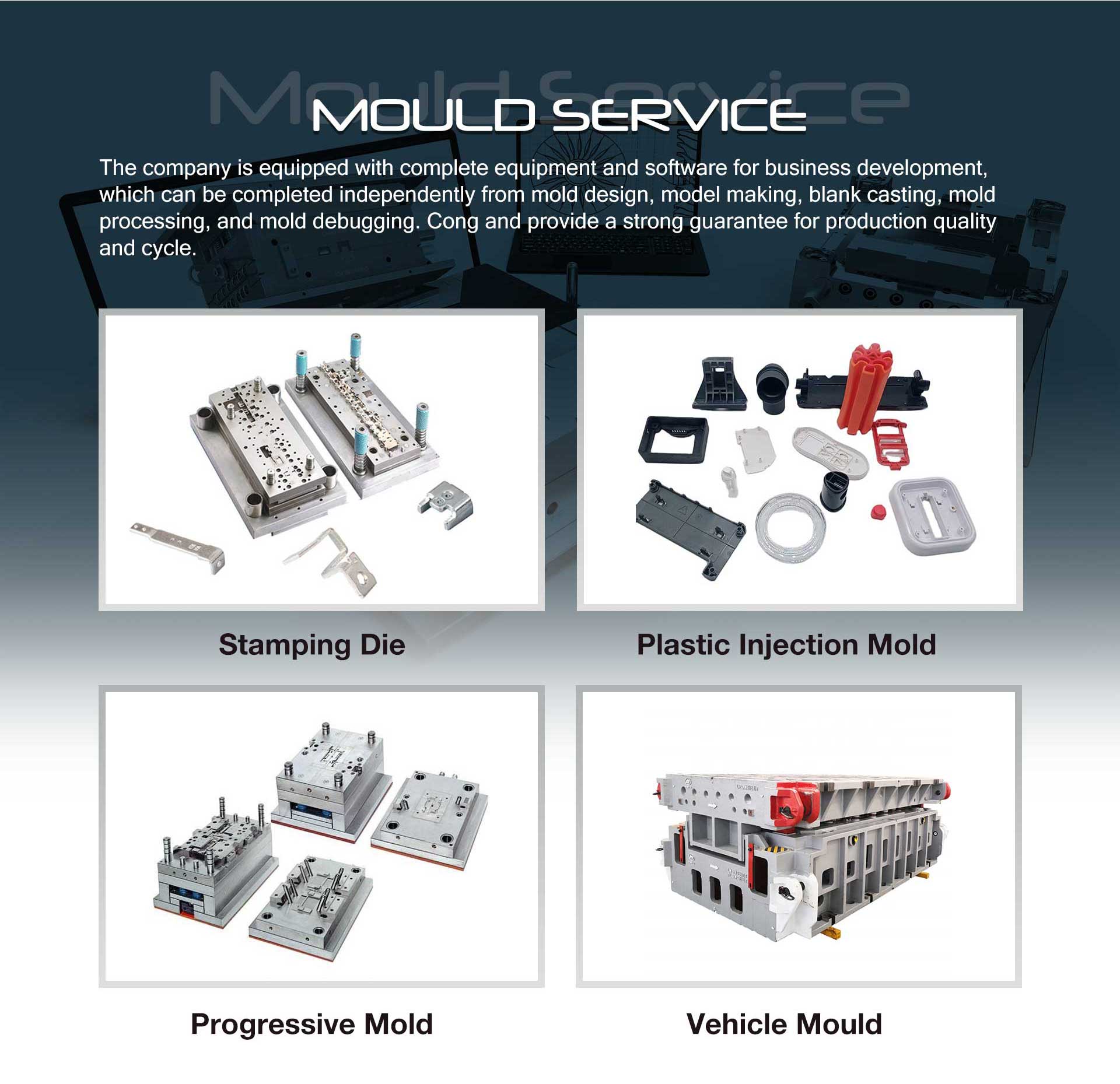

After receiving the customer’s order and product drawings, and communicating the technical de-tails in detail with the technicians, the technical department starts to design the mold. After thedesian is completed, computer simulation is carried out, and details are adjusted according to thesimulation results. Finally, the draft is finalized after the simulation is passed, and the castingdrawings are sent to Jihua for casting.

After the casting mold body is completed and tested by Jihua, it is transported to Jitai workshop.hoisted to the rough machining area for rough machining, and after passing the rough machininginspection, it is transferred to the finishing area for finishing machining. After finishing finishing.enter the mold debugging area for mold debugging. After the initial debugging is completed, theon-machine debugging is started, and the debugging is continued according to the data feedbackof the actual punched sample. The final stamped sample is sent to the customer for mold sampleverification after being tested by a three-coordinate measuring instrument. After the mold sam-ples pass the customer’s inspection, they will be finally delivered to the customer.