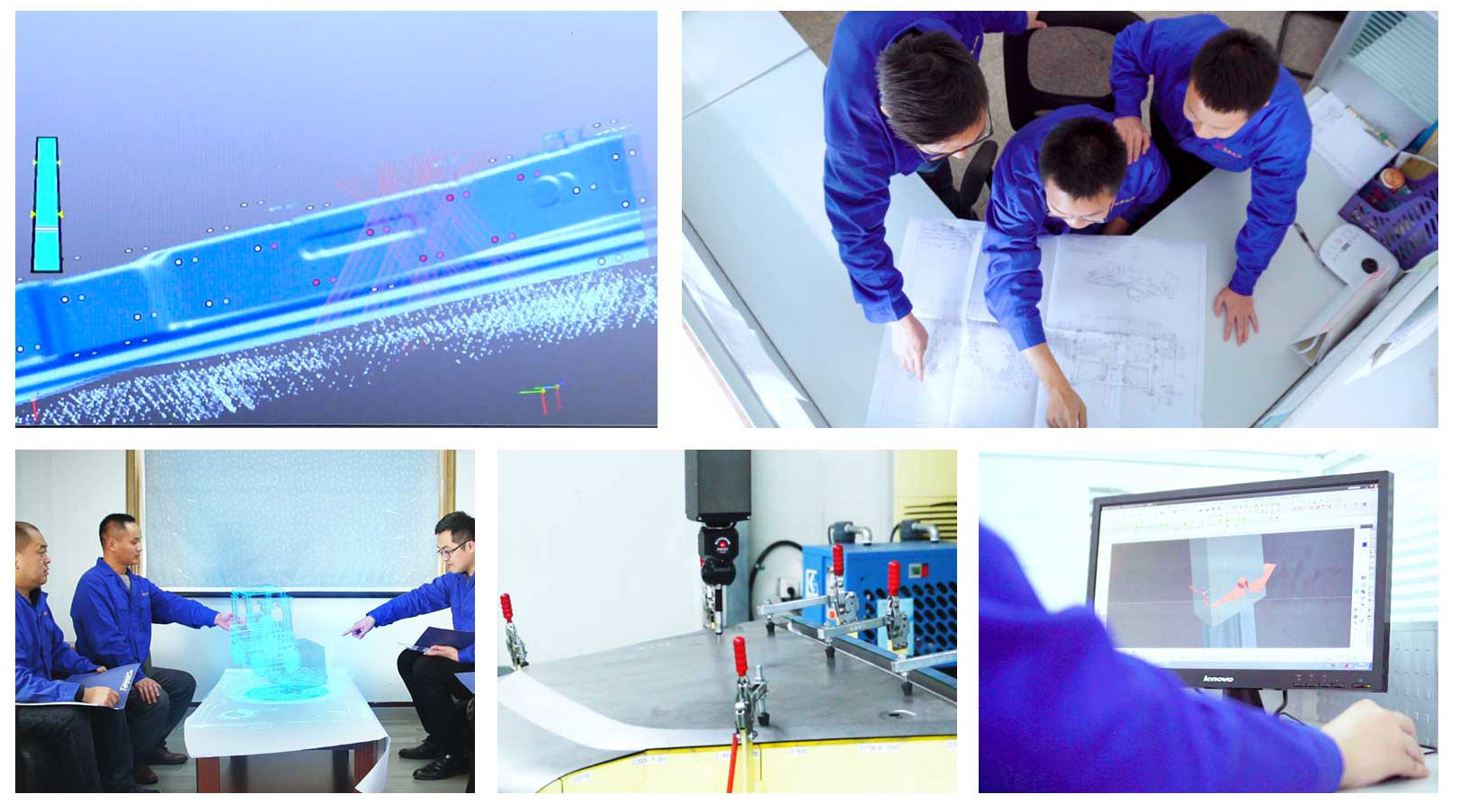

Hailong can provide product analysis report, will feedback customers with the issue arising onthe product drawing, such as the Thin thickness area, shrinkage mark, welting mark, Air ventundercuts, gate location, gate type, etc.After design finished, we’ll check on the Mould strengthpart line, cooling system, interference area, Thin thickness area, etc. To be sure the drawingprovide by Hailong is in the xcellent status for the longer products life and work efficiency forcustomers.

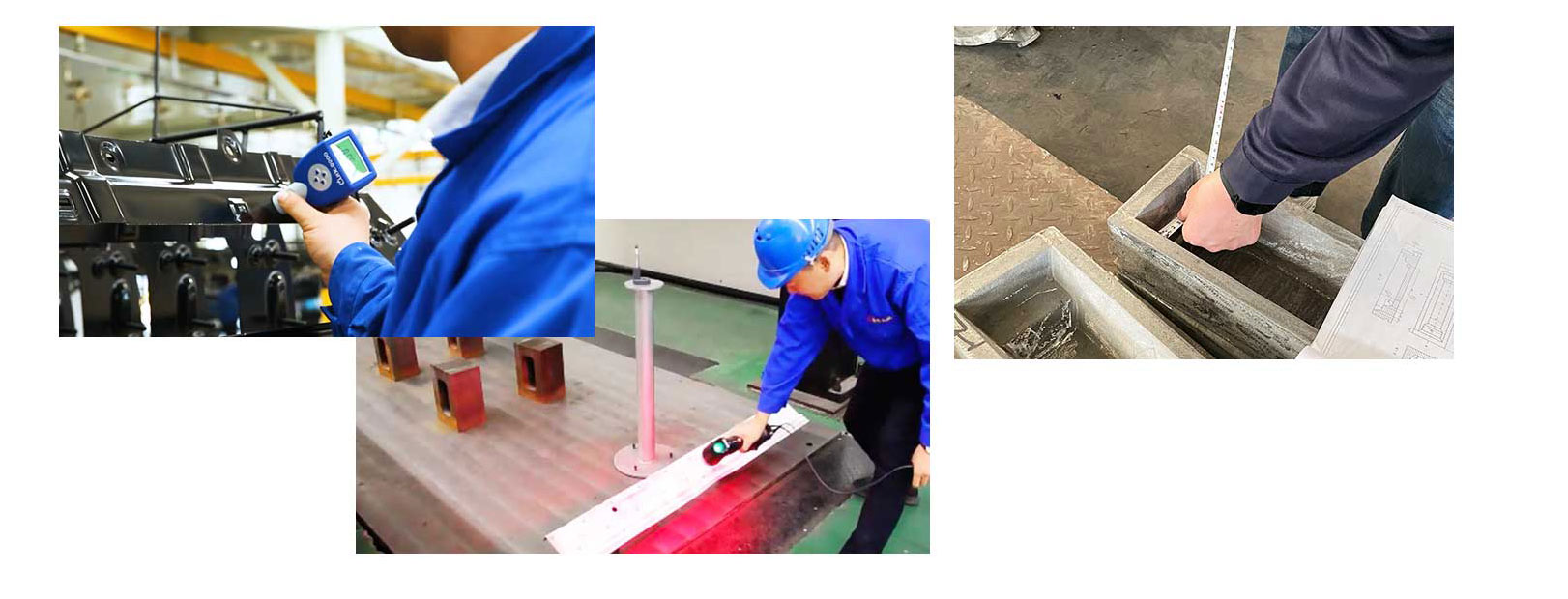

Raw material supplier are requested to provide material quality guarantee certificate and mate-rial certificate, Hailong will do inspection before acceptance.

Controlling key procedure quality and manage the project progress according to product pro-cessing documents, Hailong provide weekly progress and quality report to customer.The product technician are required to check the appearance,cooling system, assemble, pro-cess procedures carefully according to Hailong standard and customers standard.

Physical processing will be undertook as per the established procedure documents and be in-spected relatively, strictly checking on the matching between core, cavity, inserts, quide pillar.return pin, angle lifter, sliders, ejector pin, cooling system, connector,etc.

Prepare documents before shipment, such as products list, testing vedio, processing files,2D/3Ddrawings etc. For sure we’ll packing and shipping as per customer’s requirements withsafety protecting for sea and air shipment.