Mold design and production process:

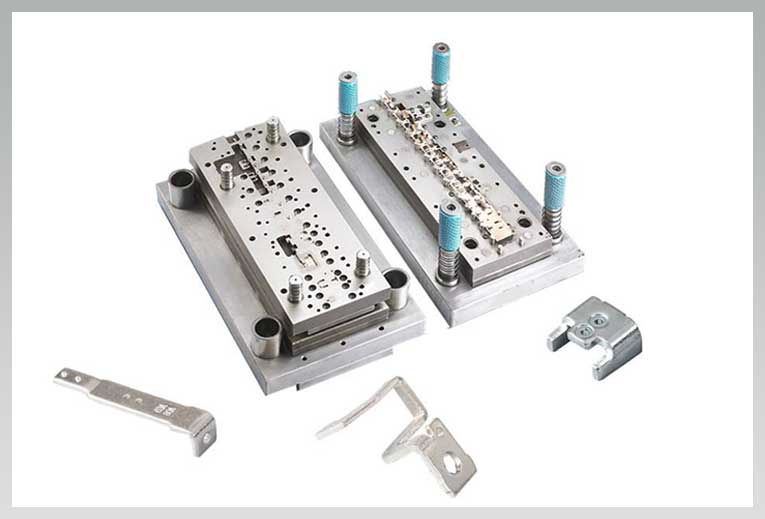

After receiving customers’ orders and product drawings, and after technicians communicated thetechnical details in detail, the technical department began to design the mold. After the design iscompleted, carry out computer simulation, adjust the details according to the simulation results.and finally finalize the design after the simulation is passed, and send the casting drawings toJihua for casting.After the casting die s completely cast in Jihua and passed the inspection, it will be transportedto Jitai workshop, hoisted to the rough machining area to start rough machining, and passed therough machining inspection, and then transferred to the finishing area for finish machining. Afterfinishing, enter the mold debugging area for mold debugging. After the initial debugging is com-pleted, start debugging on the computer, and continue debugging according to the actuastamped sample data feedback. Finally, the punched sample is tested by three-coordinate measuring instrument and sent to customers for mold sample verification. The mold samples are fi-nally delivered to the customer after passing the customer inspection.